Using CAD “computer aided design” in laser technology enhances productivity and quality of design, especially in acrylics. CAD software was first invented in 1960 for astronomers and engineers. Now, it is widely deployed in numerous industries owing to its benefits and cost-effectiveness. Nearly all digital sectors, like architectural designs, electrical schematics, laser cutting, and plastic fabrication, use CAD software.

Are you curious to know what exactly is CAD? What are its benefits, and why do we use it for accurate 3D design making? At Plexico, we have you covered with the use of the latest technology for creative acrylic display stands and magnetic knife stands using CAD. Keep reading and you will get a lot of information on CAD and the best acrylic products.

What Does CAD Stand For?

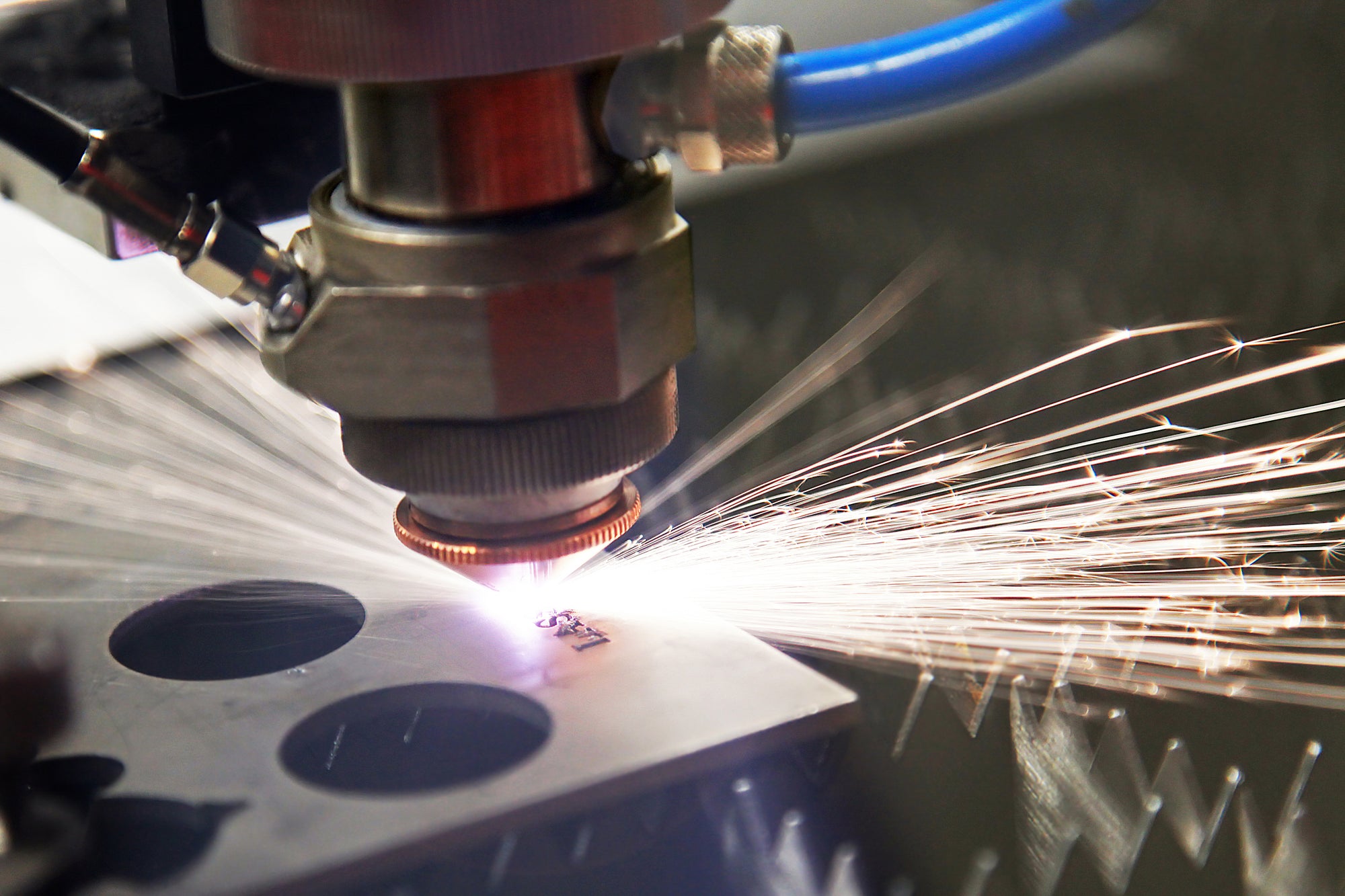

CAD refers to computer-aided design. It creates a 2D diagram of the material and 3D models of the elegant designs. CAD software is frequently used by engineers and designers to streamline the production process. CAD in laser cutting is of vital importance for creating accurate and interesting designs with smooth edges and polished finishes. In short, CAD is the magical tool or software that has made it possible to give life to seemingly impossible designs.

Most Popular CAD Software/Tools

Designers use different types of CAD software and tools depending upon the type of their work. Some tools support diverse niches. But others are tailored for specific industries like architecture and electronics.

The following CAD software is commonly used.

- AutoCAD

- OpenSCAD

- CADTalk

- IronCAD

- LibreCAD

- Catia

- MicroStation

- Inkspace

But for laser cutting, Adobe Illustrator is the gold standard CAD software for the best acrylic design creation.

Why CAD is Used In Laser Cutting Acrylics?

Laser cutting with CAD software eliminates the risk of errors and gives the best outcomes for finely detailed projects. You can easily create and transform your imagination into sophisticated acrylic and plastic designs.

Here’s the list of dominating points that make it inevitable for laser technology to use CAD.

Preview Your Design and Prototype

Most of the time, designers are not sure about the uniqueness and existence of the end product. Like, if you have been assigned a mass production of acrylic display stand by your client. Simply make the CAD file to see the end results of your first piece. After finalizing your design, run the computer and allow the laser to cut the acrylic material with maximum accuracy and precision. Now, you have your prototype ready. You can make minor changes to the prototype as per your client's suggestion without slowing the process.

We at Plexico value our client’s suggestions. We save all our designs electronically and provide prototypes to the clients for improvements if needed.

Quick Process Completion

Laser cutting with CAD is cost-effective and efficient. The process is quick because the laser follows the same pattern for all designs.

Not only it gives interesting designs on acrylic materials but also fastens product formation. It means the time a human takes for one product, laser makes more products with exact design at the same time.

Even you can make changes to the sketch without creating a whole new design.

Best Quality and Designs

Using a CAD file as a guide, the computer follows the exact pattern for cutting material. You can create the desired fractional distance on your CAD sketch with a maximum accuracy of 0.025mm. Resultantly, you can achieve a fine design with the laser pattern following the paramount detail. The digital files also make it easy to collaborate with colleagues for design discussions and improvements.

Acrylic Display Stand

Capturing client attention by displaying products was not easier before acrylic display stands. The transparent stands with novel designs advertise products dominantly. CAD makes it possible to create different stands with perfect shapes and cuts. These acrylic stands are lightweight, convenient to handle, easy to clean, and don’t break easily. Whether you own a mobile phone shop or a makeup store, Plexico acrylic display stands will help to shine your business.

Plastic Fabrication

Like other industries, CAD also serves the plastic fabrication niche for the exact designing and manufacturing of products. For custom designs, just contact Plexico. Brief us about your specifications, and we will transform them into a sophisticated plastic design.

Magnetic Knife Stand

Our magnetic knife stand is worth more than just holding the knife from slipping. It attracts clients to buy your knife without detraction. Moreover, it gives the floating effect with its transparent design made of durable acrylic material. The CAD files assist the laser in making accurate cuts and giving the design its true life.

You can visit our online shop for more acrylic products.